The benefits of smart glasses in logistics

In a fast-paced industry such as logistics, we need to look at every possibility of keeping up with the demands we face. Several studies show that the usage of smart glasses offers one way to adapt to current needs - let’s take a look at why.

Logistics handle a lot of information, all this information needs to be presented somewhere where it is easily accessible. Until recent, the most used warehouse picking solution was paper picking lists. Many studies have confirmed the inferior results of this method, why other solutions have been developed to fill its gap in both effectiveness and accuracy. Recent solutions include handheld scanners, pick by light, pick by voice, smart glasses and cart mounted displays, to name a few.

A study named An empirical task analysis of warehouse order picking using head-mounted displays has focused on comparing the usage of some of these new solutions. In the study, a head mounted display (HMD) is compared to three other picking methods, voice, paper with text instructions and paper with graphical instructions.

The experiment conducted within the study showed a clear advantage when using smart glasses with manual parts picking.

The authors found a significant difference in pick time using HMD compared to all other methods. The HMD also showed the lowest amount of errors and was ranked as the preferred choice of the tested picking methods by the participants.

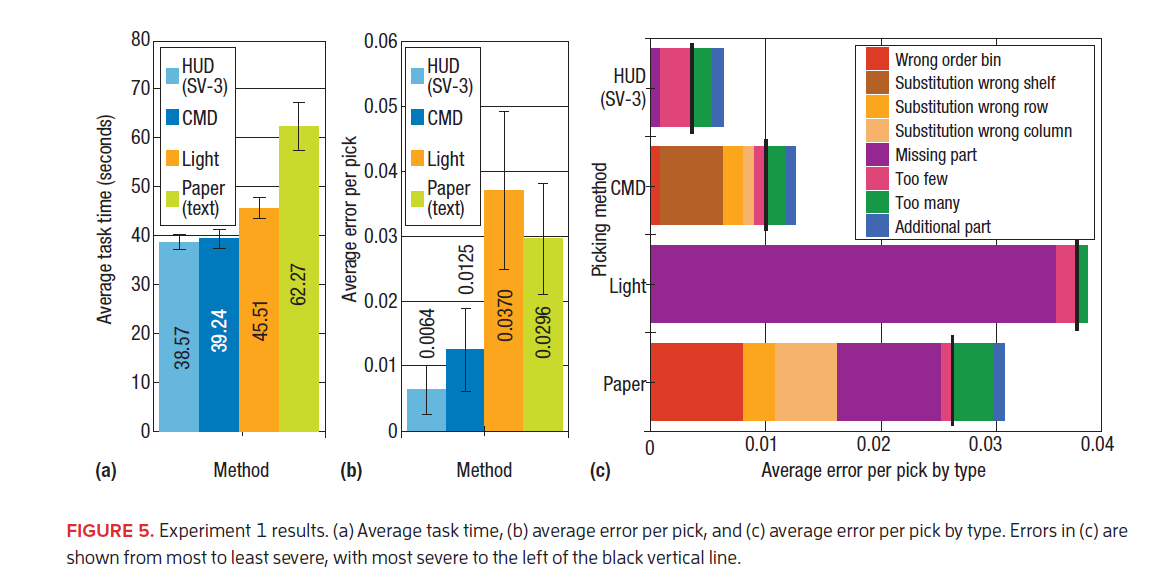

Another study, comparing pick by paper, pick by light, cart mounted display (CMD) and head up display (HUD), have reported their results in Order picking with head-up displays. They also found significantly shorter pick times when using smart glasses, compared to paper and light. The number of errors differed significantly between the different methods in the study, with the least number of errors seen when smart glasses were used.

Apart from the above mentioned experimental studies, DHL, as the first company in the industry to evaluate smart glasses, has reported reduced picking times with 15% on average. They also report a reduced onboarding and training time with 50%.

The success of smart glasses in the described experiments can be accredited the many benefits of the technology, especially when the items to pick are stored in close proximity to each other.

The most prominent improvement is given when the pickers get their hands free, not needing to handle a physical paper, or other information-holding device, at the same time as they pick items. They have the picking information continuously available and does not have to memorize what items to pick and avoids the need of adapting their work pace to a voice-input driven system. The glasses also gain advantage by using our natural way of information representation in the brain, which is image-making. All these factors, and many more, combine in to the great success of smart glasses in logistics.

Although smart glasses provenly perform very well in comparison with many other solutions, the technology is far from perfect. It is still very new and we have a lot of developmental improvements to look forward to. As the technology continues improving, the benefits will keep on increasing and logistics will find themselves in the midst of this performance boost.

References

Guo, A., Wu, X., Shen, Z., Starner, T., Baumann, H., & Gilliland, S. (2015). Order picking with head-up displays. Computer, 48(6), 16-24.

Weaver, K. A., Baumann, H., Starner, T., Iben, H., & Lawo, M. (2010). An empirical task analysis of warehouse order picking using head-mounted displays. In Proceedings of the SIGCHI Conference on Human Factors in Computing Systems (pp. 1695-1704). ACM.

https://www.logistics.dhl/global-en/home/press/press-archive/2017/dhl-supply-chain-makes-smart-glasses-new-standard-in-logistics.html